Earth’s natural capabilities are being tested at an increasingly alarming rate — pushing planetary boundaries and threatening humanity’s very existence. To help ensure a just transition, where no one is left behind, there is a need for sustainable and equitable practices across business, government and broader society. To walk our talk, KPMG has committed to reach net-zero carbon emissions by 2030, and circularity is a critical enabler in achieving our net-zero objectives. We have therefore developed a plan to promote circularity within the organization. A circular economy is a system that does not consider used products as waste but as raw materials for reuse. It aims to decouple economic growth from resource consumption, helping to create long-term value. Going circular is also key to preventing the depletion of Earth’s resources. This reduces the need to mine resources, thereby alleviating the impacts on the environment, human rights, biodiversity and the climate.

An important step in becoming circular is to identify the equipment used and evaluate our supply chain for the identified equipment. The use of laptops has been identified as one of the most material aspects for KPMG to become more circular. As a service provider, this is a physical asset that we use in high quantities. At the same time, IT equipment is an urgent concern, as it uses large amounts of rare earth metals. In a growing digital world, the demand for more state-of-the-art IT equipment will only increase.

Collaborating to close the loop

Jeroen Buurma, Head of ITS KPMG: “There is a clear objective at KPMG. We need our IT equipment to ‘go circular’.”

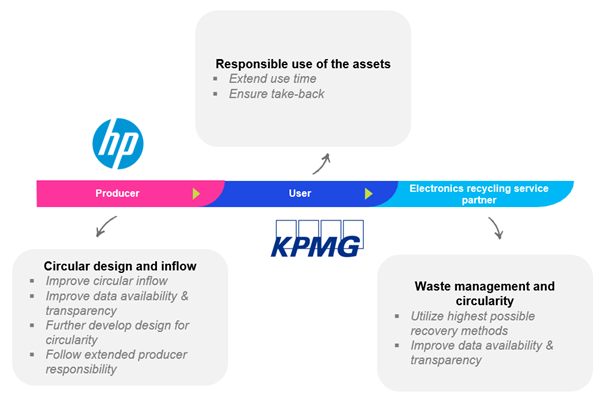

Becoming more circular can include designing for reuse and repair, using recycled materials, buying refurbished equipment, and more. However, the complexity of going circular lies in the long and complex supply chains, making it difficult to know where to start and what the key levers for impact are. Moreover, the concept of circular economy is still relatively nascent and unfamiliar to many companies. What is clear is that a transition to circularity requires collaboration across the supply chain. That is why KPMG, HP and our electronics recycling service partner joined forces to obtain actionable insights needed for the circular transition of a highly tangible asset – laptops. HP, for example, applies rigorous design principles to improve the environmental performance of their products throughout their life cycle, driving the circularity of products and materials, also known as their Design for Circularity program.

See Figure 1 below for an overview of the value chain including some key steps each actor can take to work towards becoming more circular. In connection with ‘de Week van de Circulaire Economie 2023’ (Circular Economy Week 2023), we would like to share our approach and what you can benefit from.

Figure 1: Value chain overview

“At KPMG, we have been supporting clients on their circularity journey for over a decade now. Applying the methods and experience that we offer to our clients also in the engagement with a key global supplier is how we can make an impact as consultants.” Arnoud Walrecht, Partner, Global Circular Economy lead.

To obtain actionable insights into the circularity of our used IT equipment, we applied the Circular Transition Indicators (CTI) methodology. This is a global, open-source methodology that enables businesses to measure circularity and translate the insights into strategy and actionable areas of improvement. The method was developed by the WBCSD and KPMG and is now used by thousands of companies around the world.

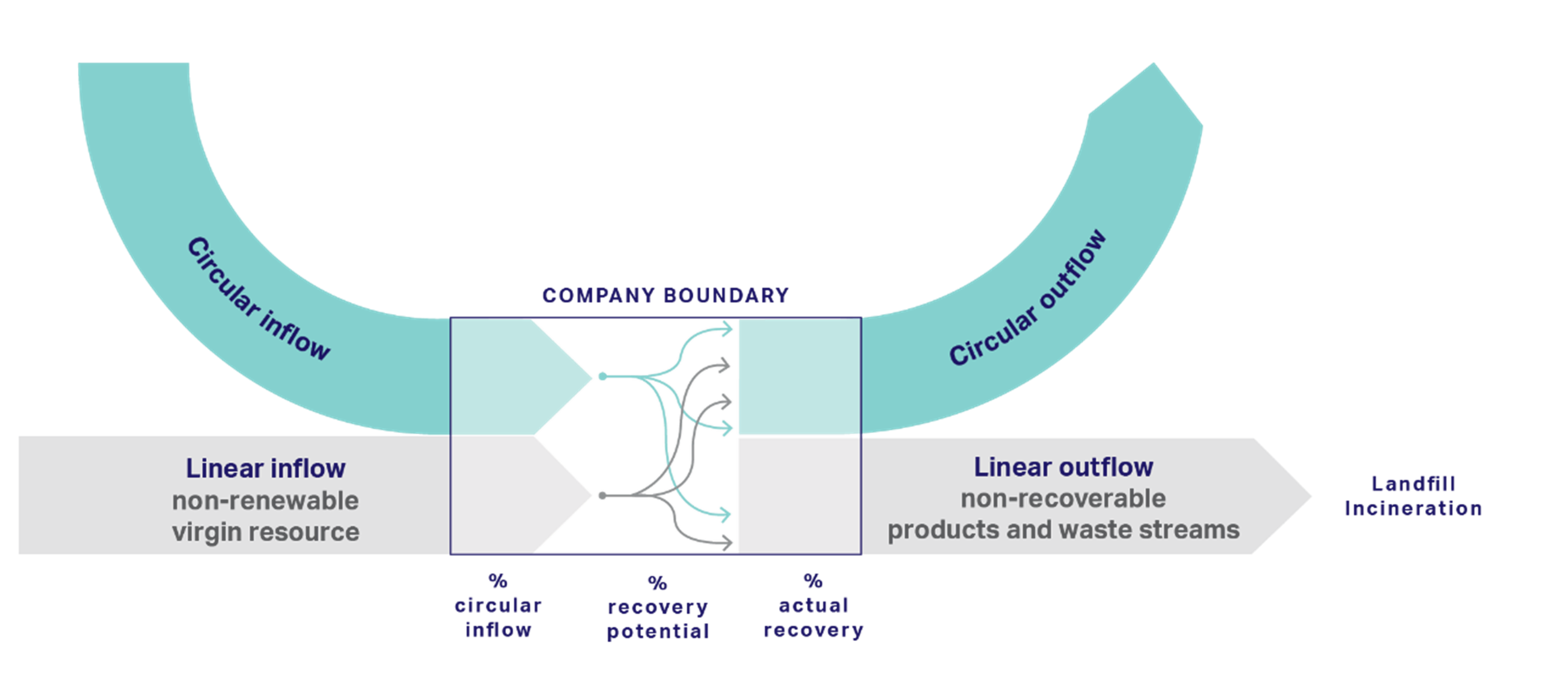

CTI, which takes a stepwise approach, makes it possible to identify the circularity of material flowing in and out of the product. An outcome of this approach is the identified circularity status of the product. Refer to Figure 2 for an overview.

Figure 2: CTI methodology summary

We decided to look at the material flows, critical materials and recovery methods, as these are critical data points in enabling a circular transition. Data collection was conducted in close collaboration with HP and our electronics recycling service partner. This close collaboration strengthened the supplier-customer relationship and gave our partners more insight into the needs of their customers.

As mentioned, the concept of circular economy is still in its infancy and has not yet been widely accepted by companies. This is why, together with HP and our recycling partner, we analyzed the landscape of circularity, and gained actionable insights. Nevertheless, we can only anticipate an increasing demand for circularity performance data with the launch of the Corporate Sustainability Reporting Directive (CSRD) in Europe.

What have we learned?

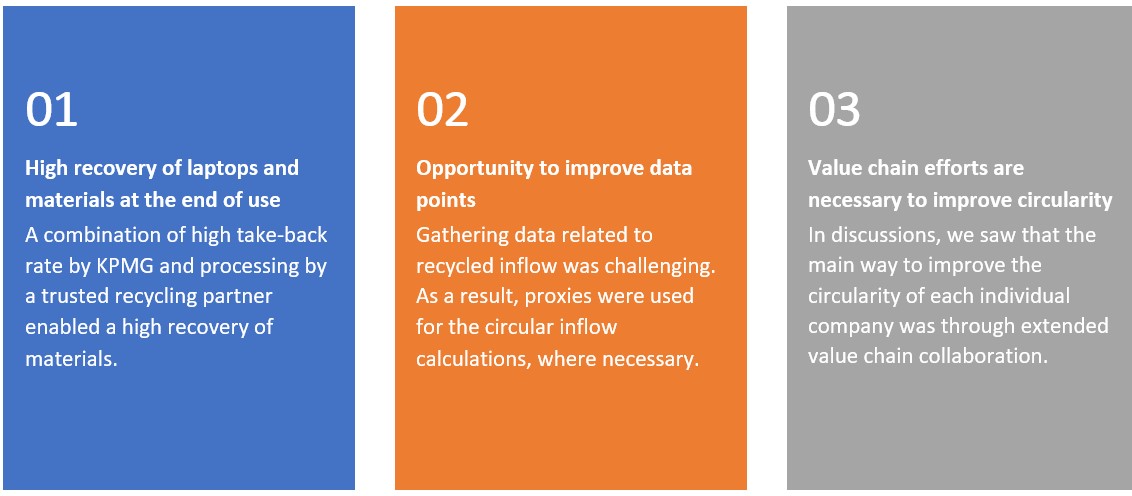

Based on the CTI analysis performed, we learned three main lessons:

Circularity is an important building block for HP’s journey towards becoming the most sustainable and just tech company.

Titia Schutten, manager Corporate Responsibility: “As part of Our Impact Plan, we have developed a plan to promote circularity and help KPMG become a circular organization. Our suppliers, such as HP, play a crucial role in delivering on those commitments. Circularity is also a critical enabler to achieve our net-zero goals.”

These lessons lay the foundation for our value chain collaboration moving forward.

What’s next?

The data points obtained from applying the CTI methodology to the use of our laptops at KPMG Netherlands have been converted into actionable insights for each individual partner. Together, we investigate how circularity efforts and data points among our partners can be further improved so that we can make an impact together.

In addition to hosting roundtable discussions within the IT industry to increase circularity, KPMG also plans to broaden this assessment and collaboration to other physical assets and develop a strategy to support our transition to circularity.

Arnoud Walrecht, Partner KPMG Sustainability